China wholesale Lockout & Tagout Stations - Electrical PC Lock out Loto Station LS11-16 – Lockey

China wholesale Lockout & Tagout Stations - Electrical PC Lock out Loto Station LS11-16 – Lockey Detail:

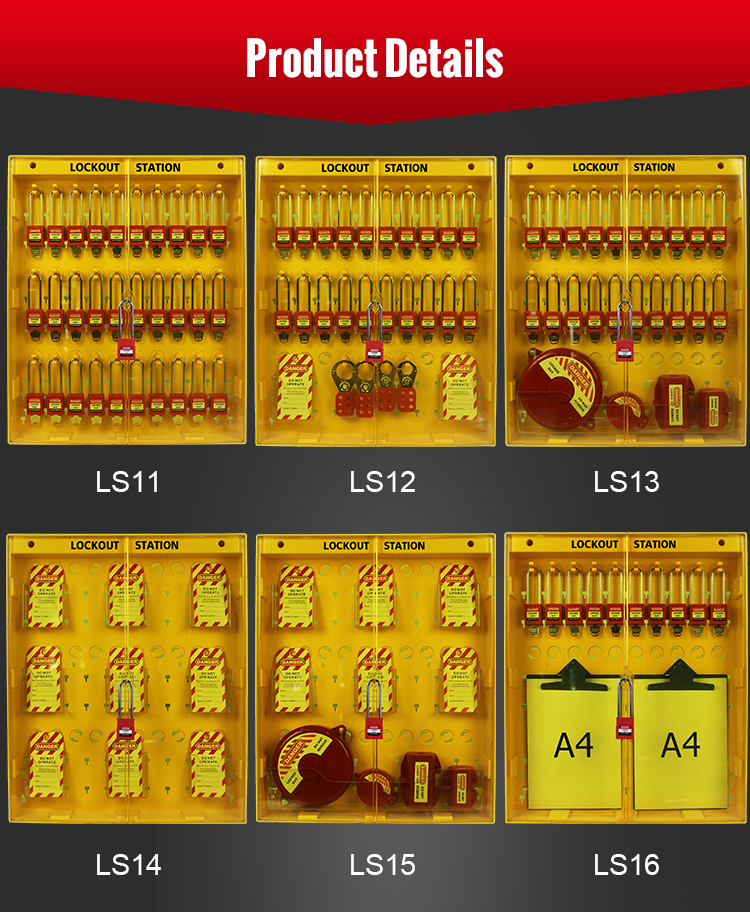

Combined Lockout Station LS11-16

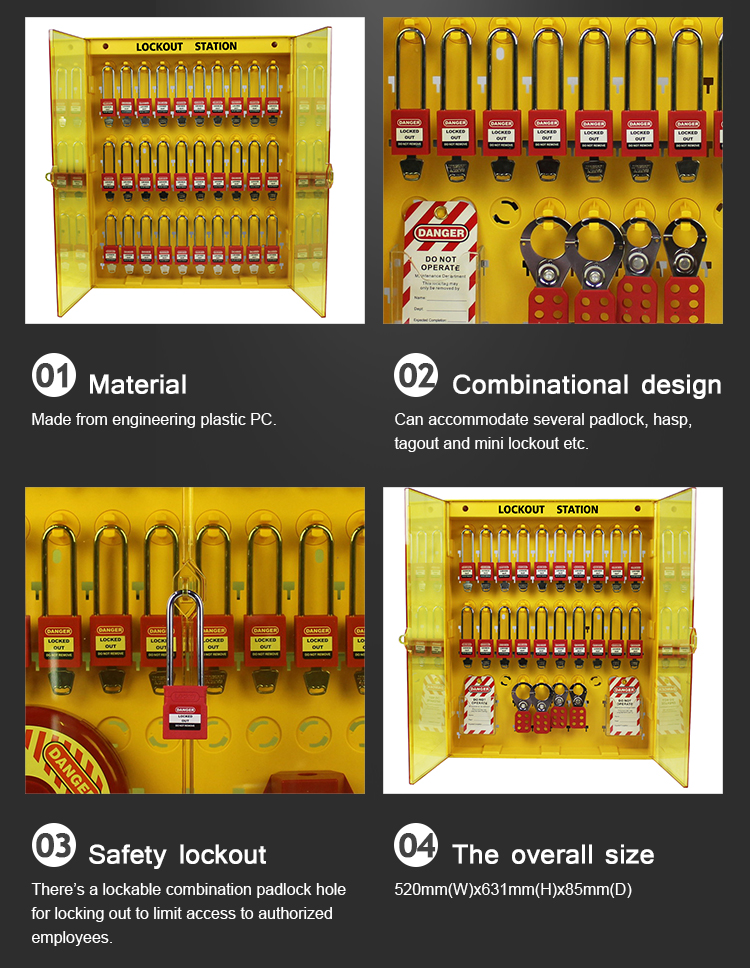

a) Made from engineering plastic PC.

b) It’s one piece design, with a cover to lock out.

c) Can accommodate several padlock, hasp, tagout and mini lockout etc.

d) There’s a lockable combination padlock hole for locking out to limit access to authorized employees.

e) The overall size: 520mm(W)x631mm(H)x85mm(D).

| Part No. | Description |

| LS11 | Can accommodate 60 padlocks. |

| LS12 | Can accommodate 40 padlocks, 8 hasps and tags. |

| LS13 | Can accommodate 40 padlocks and mini lockouts. |

| LS14 | Can accommodate a number of lockout tags. |

| LS15 | Can accommodate a number of tags and mini lockouts. |

| LS16 | Can accommodate 20 padlocks and 2 writing boards. |

Project Details

Categories:

Lockout tagout procedures

1) Preparation

Hold a report meeting before the start of work, define the form, scale, risk, device and corresponding inspection steps of the energy control, register the equipment to be locked, and fill in the Lockout Tagout work sheet. The authorized person notifies all affected persons in the lock-controlled area.

2) stop

Authorize personnel to shut down and test machinery and equipment and conduct planned shutdowns to avoid additional risks.

3) the isolation

Close switches, valves and other isolation devices, to isolate dangerous energy, to avoid dangerous energy connected to the machine, equipment, if the conditions permit, but also as far as possible to set the closed physical railings.

4) Energy release

The stored and remaining energy must be safely released or eliminated, uninterrupted inspection until the completion of the operation, so that there is no possibility of energy accumulation, to achieve zero energy state.

5) Lockout tagout

Authorize personnel to implement Lockout Tagout for the equipment that has completed isolation

In the locked-control state, no one is allowed to attempt to operate switches, valves or other energy isolation devices. Removing the tag of someone else’s padlock is equivalent to removing the padlock and prohibits similar behavior. Uniform standard identification plates should be used, containing the following information: Unauthorized use of locked equipment or machines is prohibited; The removal of signage plates is prohibited; Sign board owner, date and reason for listing. The signboard should be firmly hung to ensure that it will not fall off easily or be accidentally knocked off by staff.

6) test

After confirming that all people are far away from the designated machine and equipment, a normal operation test shall be conducted by an authorized person to confirm that the power supply of the machine and equipment required to be locked has been cut off and cannot work.

7) work

Carry out installation, maintenance, cleaning and other construction operations.

8) Unlock the cards

Before unlocking the lock, the person shall check the equipment and area in his/her charge, confirm that the related work of the machine and equipment has been completed, and then remove the lock and tag of himself/herself and register in the work sheet. When there is a special situation that can’t get in touch with the relief personnel, the supervisor should complete the inspection on their behalf. After repeatedly confirming that there is no problem, the debugging manager can order to cut off or destroy the lock and mark, and report to the site manager after thoroughly investigating the cause of the incident.

Product detail pictures:

Related Product Guide:

Lock out tag out case story

Compliance by all relevant personnel

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of China wholesale Lockout & Tagout Stations - Electrical PC Lock out Loto Station LS11-16 – Lockey , The product will supply to all over the world, such as: Angola, Egypt, Kuwait, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!

Products categories

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top