Chinese Professional Group Loto Box - Waterproof Lockout Tagout Tool Bag LB02 LB03 – Lockey

Chinese Professional Group Loto Box - Waterproof Lockout Tagout Tool Bag LB02 LB03 – Lockey Detail:

Safety Portable Lockout Bag LB02&LB03

a) Made from durable waterproof nylon fabric.

b) Can custom made the sign on the lockout bag surface.

c) With easy carrying hand straps and a shoulder strap.

| Part No. | Description |

| LB02 | 350mm(L)×230mm(H)×210mm(W) |

| LB03 | 390mm(L)×290mm(H)×210mm(W) |

Project Details

Categories:

Lockout bag

Perform the isolation

Production and maintenance employees also need to follow cleaning procedures, PPE specifications, and lockup procedures when implementing energy isolation programs.

Transfer and drain the residual chemicals in the process system in strict accordance with the cleaning procedures; At the same time, according to the process characteristics of the process pipeline cooking, cleaning or purging, to ensure that the residual chemicals as far as possible out of the operating area of the pipeline.

After the process system is cleaned up, it is necessary to test the process system to ensure that the amount of residual chemicals is below the minimum explosive limit and toxicity, and confirm and verify the effectiveness of cleaning.

For the valves, rotating equipment and energy sources in the energy isolation plan, it is also necessary to Lockout the tagout after the field operation according to the energy isolation plan to ensure that it is not misoperated by other personnel and ensure the integrity of the energy isolation plan in the maintenance or project process.

The energy isolation red card must be hung on the valve or equipment at the energy isolation point to inform and warn others not to operate. The red card indicates operator and date, isolation point equipment status, type of power source, etc.

Similarly, the valve at the energy isolation point should be locked so that others can not operate the valve equipment. The key of the lock shall be placed in the energy isolation lock box. After the energy isolation is completed, the lock box shall be locked by the production personnel, and the production personnel shall keep the key.

After the on-site maintenance team representatives confirm the energy isolation plan and install the energy isolation blind plate, the energy isolation box shall be locked at the same time. At this point, the on-site energy isolation program is protected by both the production and maintenance teams.

The maintenance team must confirm and verify the energy isolation plan on site before starting work on site, such as confirming the state of related valves, no material discharge from the pouring valve, confirming the isolation of electric energy such as switching equipment and measuring voltage, etc., before officially starting work on site.

The maintenance representative can not remove the maintenance lock from the energy lock box until the field repair work is completed and handed over to the production unit. Only then can the production personnel remove the energy isolation points on the site one by one, record and confirm them on the energy isolation schedule one by one, and restore them to the state of process pipelines and equipment before maintenance.

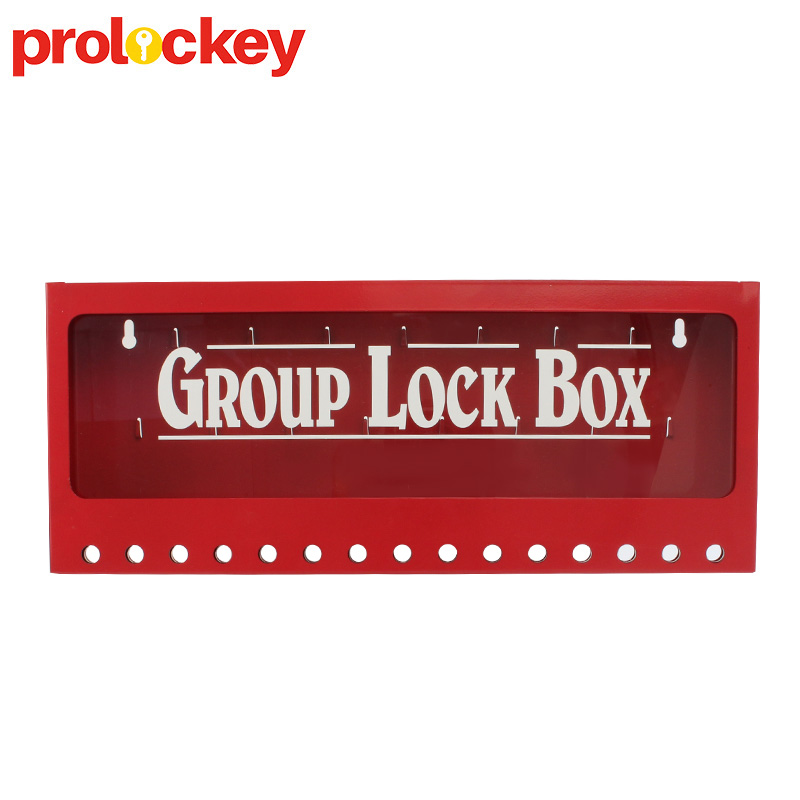

Product detail pictures:

Related Product Guide:

Generator energy isolation-Lock out tag out

Complex locking procedures

The corporation upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will proceed to provide aged and new buyers from home and abroad whole-heatedly for Chinese Professional Group Loto Box - Waterproof Lockout Tagout Tool Bag LB02 LB03 – Lockey , The product will supply to all over the world, such as: Belgium, The Swiss, Palestine, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Products categories

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top