Chinese wholesale Lockout Management Station - Open Lockout Station Board LS51-LS23 – Lockey

Chinese wholesale Lockout Management Station - Open Lockout Station Board LS51-LS23 – Lockey Detail:

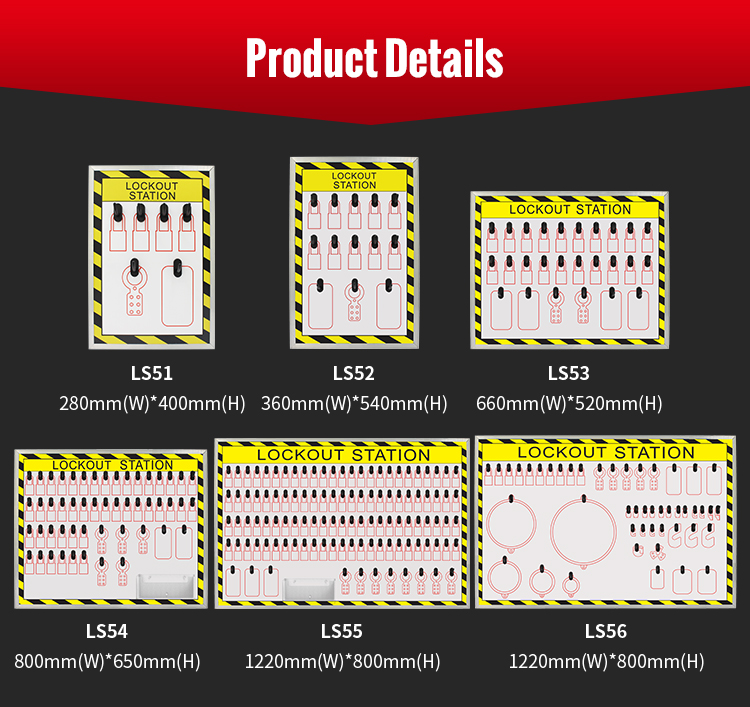

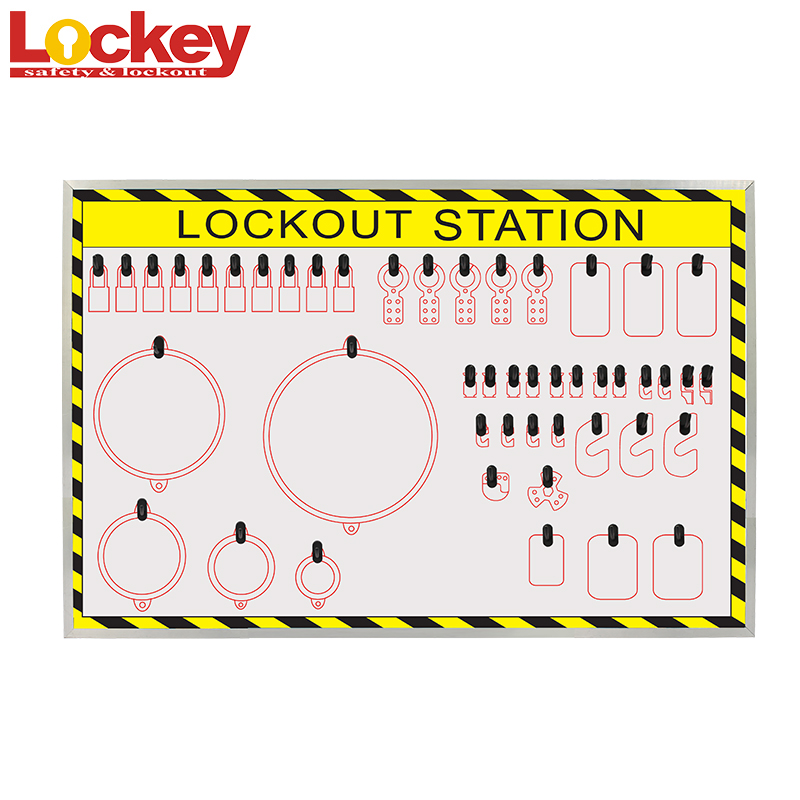

Part No.: LS51-56

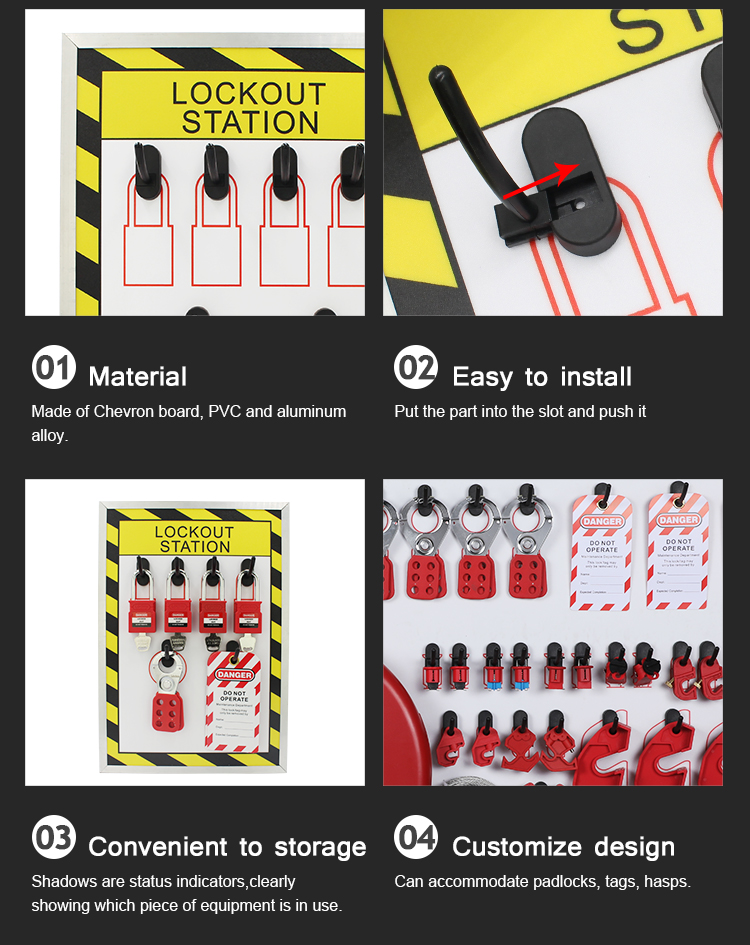

a) Made of Chevron board, PVC and aluminum alloy. .

b) Shadow contour is convenient to inventory and storage.

c) Shadows are status indicators,clearly showing which piece of equipment is in use.

d) Can customize design and logo etc.

|

Part No. |

Description |

|

LS51 |

280mm(W)*400mm(H) |

|

LS52 |

360mm(W)*540mm(H) |

|

LS53 |

660mm(W)*520mm(H) |

|

LS54 |

800mm(W)*650mm(H) |

|

LS55 |

1220mm(W)*800mm(H) |

|

LS56 |

1220mm(W)*800mm(H) |

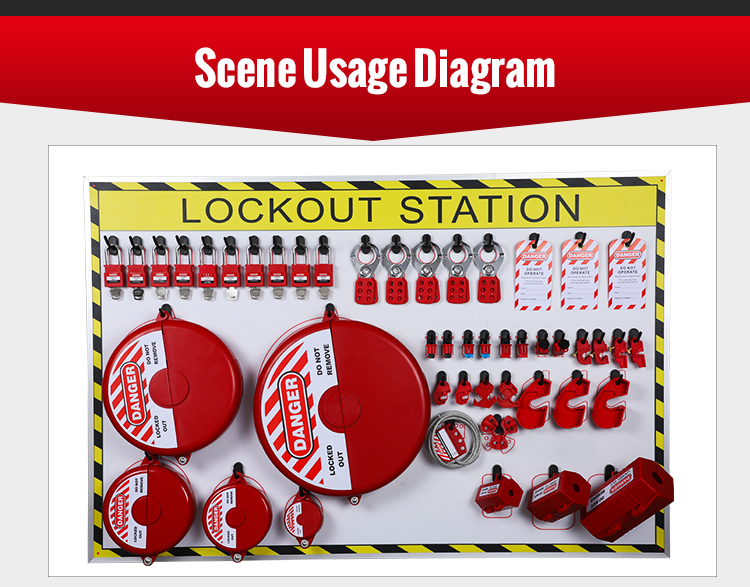

Production safety is the top priority of production management of enterprises. Doing a good job in production safety can not only effectively guarantee the safety and health of employees, but also better safeguard the survival and development of enterprises. According to statistics, at present, about 10% of the world’s production safety accidents are caused by dangerous energy sources that have not been effectively controlled. Accidents not only cause harm to the safety of staff, but also easy to damage machinery and equipment, resulting in the production of factories, affecting the benefits of enterprises. The research shows that the dangerous energy can be controlled effectively and the accident rate can be reduced by 30%~50% by strictly observing the Lockout Tagout system in the production commissioning.

Lockout Tagout has long been paid attention to abroad. Each country has formulated relevant regulations and standards. Meanwhile, these regulations are highly valued by enterprises and employees, and are strictly implemented in production, so the accident rate is effectively reduced. In China, due to the relative lack of enterprise management and the lack of safety awareness of the staff, the Lockout Tagout system has not been well implemented, so the production accident rate remains high.

Basic principles of lockout tagout

Lockout tagout is an occupational safety and health standard method of preventing personal injury by isolating or locking certain hazardous energy sources. Among them, dangerous energy source mainly refers to a kind of energy that will cause damage or damage when it is suddenly opened or released, including electric energy, mechanical energy, water energy, chemical energy, radiant energy, heat energy, kinetic energy, storage energy and potential energy, etc. So required equipment, mechanical, electrical, hydraulic or pneumatic system in installation, maintenance, operation, debugging, the process of inspection, cleaning and maintenance, staff shall strictly implement Lockout tagout procedures, abide by the power equipment, machine of accidental start, to prevent the release of the dangerous energy, causing injuries and property losses.

Product detail pictures:

Related Product Guide:

Lockout/Tagout Standard

Mining company-Lockout Tagout

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for Chinese wholesale Lockout Management Station - Open Lockout Station Board LS51-LS23 – Lockey , The product will supply to all over the world, such as: Miami, Salt Lake City, Chicago, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

Products categories

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top