High Quality Safety Lockout Box - Waterproof Nylon Portable Lockout Bag Tool Bag LB51 – Lockey

High Quality Safety Lockout Box - Waterproof Nylon Portable Lockout Bag Tool Bag LB51 – Lockey Detail:

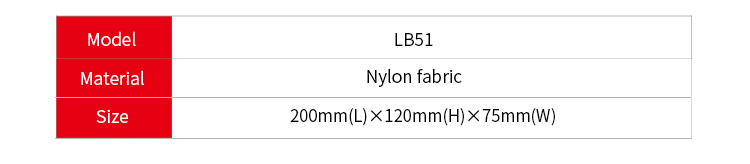

Safety Bag LB51

a) Made from durable waterproof nylon fabric.

b) Light-weight and easy to carry .

c) Can customize the sign on the lockout bag surface.

| Part No. | Description |

| LB51 | 200mm(L)×120mm(H)×75mm(W) |

Project Details

Categories:

Lockout bag

Security of energy isolation

The test validation procedure is a necessary step and cannot be omitted. In this case, the staff have not before the equipment is put into operation to complete the test of the function of the equipment, especially the emergency stop button on the mud pump function without testing, lead to drive motor wiring error is not found, field repair of the mud pump vice driller also does not have to test the button function, more didn’t go to confirm the energy isolation is effective, the last nearly have casualties of the consequences.

The Lockout Tagout procedure is a protective standard for dangerous energy control (29 CFR 1910.147) issued by OSHA (Occupational Safety and Health Administration) in 1989. The revised standard describes the Lockout Tagout requirements for the general industry and requires the authorized employee to confirm that the isolation and power off of the machine or equipment has been completed prior to the commencement of work on the machine or equipment that has been locked or labeled. Studies have shown that the energy control program can reduce the casualty rate by 25 to 50 percent. About 10% of all industrial accidents are caused by the failure to properly control hazardous energy. According to the U.S. OSHA, about 250,000 accidents are involved each year, of which 50,000 result in injuries and more than 100 are fatal.

Lockout tagout conclusion

Rules and regulations are usually established based on relevant professional theories and the experience and lessons of many relevant events in the western region for a long time, summarized and gradually improved. Many rules and regulations have a lot of hard lessons behind them,

It is a powerful measure for safe production and safeguarding the personal safety of employees. It is a constraint, but it is also a guarantee. The former is the form and the means; the latter is the end.

Equipment design, manufacturing, installation, use and maintenance of each link of the corresponding standards and requirements, which is the employee safety barrier, once this barrier is broken, will lead to tragedy.

Events more reason is the management of safety awareness is not enough, in the process of production management and did not reflect the safety of the people-oriented concept, the pursuit of production rate and production efficiency, leads to deviation in the direction of management, the safety inputs (including equipment and the investment of time) was compressed and cause a downturn of the frequent accidents of safety performance, so that the loss of market. A short-sighted view of reduced security spending is unlikely to see delayed security benefits.

In the execution of the Lockout Tagout procedure, one should abandon the chance and strictly follow the requirements, rather than be a formality and go through the motions of dealing with checks. Only by carefully following the requirements can we ensure the safety of employees.

Product detail pictures:

Related Product Guide:

How to help implement an effective lockout/tagout program

Lockout/Tagout Standard

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for High Quality Safety Lockout Box - Waterproof Nylon Portable Lockout Bag Tool Bag LB51 – Lockey , The product will supply to all over the world, such as: Doha, Serbia, Nicaragua, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we are going to be pleased to serve you.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

Products categories

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top