News

-

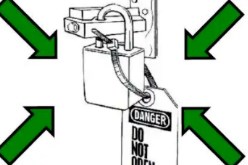

How lockout tagout works

OSHA Guidelines Guidelines as prescribed by OSHA covers all sources of energy, including—but not limited to—mechanical, electrical, hydraulic, pneumatic, chemical, and thermal. Manufacturing plants would typically require maintenance activities for one or a combination of these sources. LOTO, as ...Read more -

What is Lockout Tagout? The Importance of LOTO Safety

What is Lockout Tagout? The Importance of LOTO Safety As industrial processes evolved, advancement in machineries started to require more specialized maintenance procedures. More serious incidents occurred that involved highly technological equipment at the time causing problems for LOTO Safety. ...Read more -

Lockout/Tagout Program:Control of Hazardous Energy

1. Purpose The purpose of the Lockout/Tagout program is to protect Montana Tech employees and students from injury or death from the release of hazardous energy. This program establishes the minimum requirements for isolation of electrical, chemical, thermal, hydraulic, pneumatic, and gravitation...Read more -

4 Benefits of Lockout Tagout

4 Benefits of Lockout Tagout Lockout tagout (LOTO) is viewed by many frontline workers as burdensome, inconvenient or production-slowing, but it is critical to any energy control program. It is also one of the most important OSHA standards. LOTO was one of federal OSHA’s top 10 most frequently c...Read more -

Group Lockout Procedures

Group Lockout Procedures Group lockout procedures give the same level of protection when multiple authorized employees need to work together to perform maintenance or service on a piece of equipment. A key part of the process is to designate a single responsible employee who is in charge of lock...Read more -

Review the Lockout Tagout procedure

Review the Lockout Tagout procedure The locking procedures should be audited by the department heads to ensure that the procedures are being implemented. The Industrial Safety Officers should also conduct random checks on the procedures, including: Are the relevant staff notified when locking? A...Read more -

The main points of LOTO practice are as follows

The main points of LOTO practice are as follows: Step 1: What you must know 1. Know what hazards are in your equipment or system? What are the quarantine points? What is the listing procedure? 2. Working on unfamiliar equipment is a danger; 3.only trained and authorized personnel can lock; 4. Onl...Read more -

Equipment maintenance -LOTO

Equipment maintenance -LOTO When equipment or tools are being repaired, maintained or cleaned, the power source associated with the equipment is cut off. This prevents the device or tool from starting. At the same time all energy (power, hydraulic, air, etc.) is turned off. The purpose: to ensure...Read more -

Why Lock-Out, Tag-Out Is Vitally Important

Every day, spanning a multitude of industries, normal operations are put on hold so that machinery/equipment may undergo routine maintenance or troubleshooting. Every year, compliance with the OSHA standard for controlling hazardous energy (Title 29 CFR §1910.147), known as ‘Lockout/Tagout’, prev...Read more -

Locks Out The Entire Electrical Panel

The Panel Lockout is a OSHA compliant, award winning, circuit breaker lockout tagout device. It locks out circuit breakers by locking out the entire electrical panel. It attaches to the panel cover screws and keeps the panel door locked. The device encapsulates two screws which prevents the panel...Read more -

Lockout Tagout (LOTO) Kits

Lockout Tagout (LOTO) Kits Lockout Tagout Kits keep all of the necessary devices handy which are required to comply with OSHA 1910.147. Comprahensive LOTO Kits are available for electrical, valve, and general lockout tagout applications. The LOTO Kits are specifically manufactured from rugged, l...Read more -

Improved machine design helps to improve lock/tag security rule management

Industrial workplaces are governed by OSHA rules, but this isn’t to say that rules are always followed. While injuries happen on production floors for a variety of reasons, of the top 10 OSHA rules that are most often ignored in industrial settings, two directly involve machine design: lock...Read more