News

-

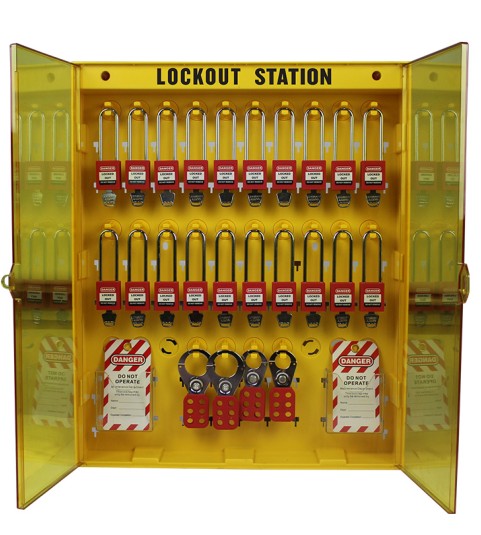

Valve control -Lockout/Tagout

How do you manage the risk of injury when you open flanges, replace valve packing, or disconnect loading hoses? The above operations are all pipeline opening operations, and the risks come from two aspects: first, the hazards existing in the pipeline or equipment, including the medium itself, the...Read more -

Mechanical injury accident

There must be a shaft cover: there should be a protective cover for the rotating roller, to prevent the hair, collar, cuff, etc. of the staff from being involved in the damage, such as the roller of the line head of the workshop, the drive shaft of the lathe, etc. There must be a cover: there are...Read more -

Mechanical isolation -Lockout/Tagout

Because the moving parts of mechanical equipment are not effectively isolated, the production safety accidents of casualties caused by people entering dangerous areas being squeezed by the activated equipment often occur. For example, in July 2021, a worker in a Shanghai company violated the oper...Read more -

Prevent accidental startup of the device

How to prevent accidental startup of equipment with reasonable compliance? In fact, this issue has long been an international standard, namely Safety of Machinery — Prevention of Unexpected Startup ISO 14118, which is currently updated to 2018 edition. There is also a corresponding national...Read more -

Energy Company -Lockout Tagout

Energy companies and Lockout Tagout equipment can be said to be inseparable, in order to achieve the highest level of safety production, major energy companies will invest millions of Lockout Tagout equipment for use during maintenance. As one of the leading companies in the industry, Lockey prov...Read more -

All relevant personnel LOTO compliance

The Lockout tagout process is very effective, but it is not simple, so it should not be learned before going inside the logistics equipment. Safe entry into the machine and Lockout tagout operations must be performed only by trained and authorized personnel. Considering that the maintenance work ...Read more -

How to use Lockout Tagout to enter logistics equipment safely?

1.Distinguish the types of work Operations into logistics equipment can be divided into two types. The first is to have to deal with simple routine, repetitive operations such as dropping containers and trays, and to do so within sight and to follow procedures for safe entry into the machine. Sec...Read more -

Lock out tag out-Steel mill risks

1. Do not wear safety belt when working at height On April 25, an inspection found that the construction workers of Shandong Metallurgical Design Institute Co., Ltd. climbed down to the bottom of the rainwater collection pond scaffold from the material yard of Zhongjin Construction Project in Yul...Read more -

Lockout tag-The air in the generator is replaced with hydrogen

I. Preparations are as follows: Steam turbine sealing oil system and lubricating oil system are put into operation, and the turning device is in a static or rotating state. Contact maintenance personnel to prepare about 60 bottles of carbon dioxide and transport them to the bus bar. Contact chemi...Read more -

Henan rescue-Lockout tagout

Zhongzhao village is located in a low-lying area, which is prone to severe flooding when it rains. This time, severe floods occurred due to the infrequent heavy rainfall, which damaged roads, houses, communications and other infrastructure in the village and led to disruption, directly affecting ...Read more -

Rectification operation violation behavior

Hine law For every serious accident, there are 29 minor accidents, 300 near-misses and 1,000 potential accidents. According to the statistical analysis of the accident, there are few objective factors, few equipment factors, and most of them are human factors: there are paralysis and fluke mental...Read more -

Lockout Tagout validation pilot work

In order to put an end to the unsafe factors of people, starting from the concept of essential safety and effectively preventing injuries caused by operators’ misoperations, copper Branch took power workshop as a pilot to carry out the implementation of energy isolation “Lockout tagou...Read more