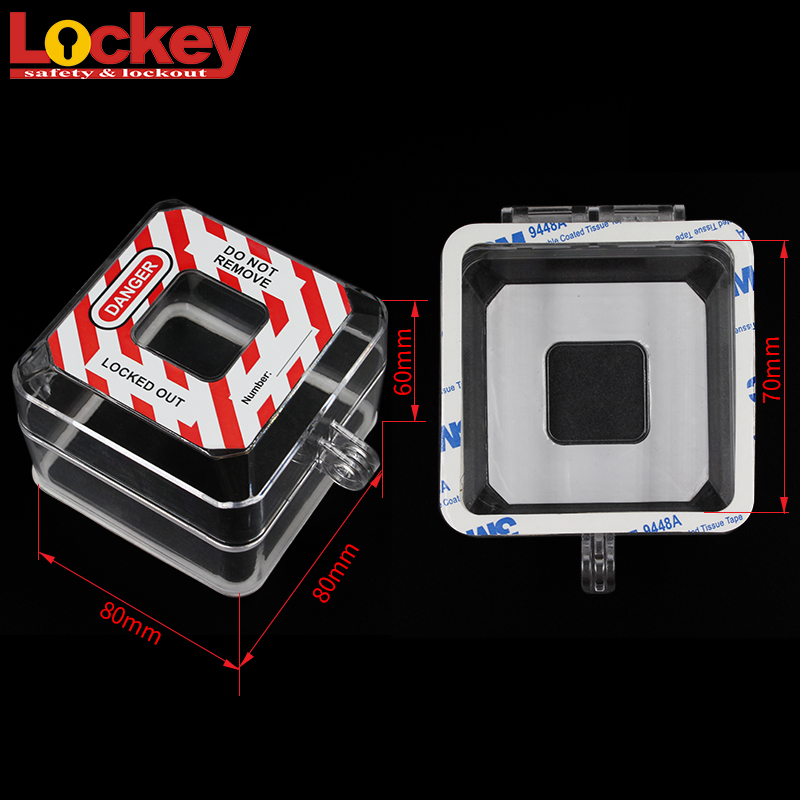

Here’s another example of a lockout tagout case: A team of electricians schedules maintenance on a switch panel that supplies power to a large manufacturing plant. Before commencing work, the electrician will isolate and de-energize the switchgear panel following a lock-out, tag-out procedure. The electrician begins by identifying all energy sources that power the switch panel, such as incoming power and backup generators. They also identify all stored energy in the panels, such as capacitors and batteries. Next, the electrician isolates all energy sources by shutting off incoming power and disconnecting backup generators. They also discharge any energy stored in the panel by using discharge resistors. Electricians then apply lock-out tags to each energy and switch panel. They use padlocks and tags to protect the incoming power and generators, and covers to prevent anyone from accessing the capacitors and batteries. After making sure that all lockouts are properly secured, the electrician begins the maintenance work. They perform visual inspections, test circuit breakers and other components, and replace any damaged components. After the maintenance work is complete, the electrician removes all lockouts and reconnects all energy sources. They also test the switch panel to make sure it is working properly and there are no loose components. This lock-out tag-out box keeps electricians safe from unintentional activation of switchgear panels and keeps the facility running safely after maintenance work is complete.

Post time: Jun-03-2023