Subheading: Ensuring Safety and Compliance in the Workplace

Introduction:

In any industrial or commercial setting, safety is of paramount importance. Employers have a legal and moral obligation to protect their employees from potential hazards, especially when working with electrical equipment. One effective method to enhance safety and prevent accidents is through the implementation of electrical lockout procedures. In this article, we will delve into the concept of electrical lockout, its significance, and the steps involved in its proper execution.

Understanding Electrical Lockout:

Electrical lockout is a systematic procedure that involves isolating and de-energizing electrical equipment to prevent accidental energization during maintenance, repairs, or servicing. It ensures that machinery or equipment cannot be inadvertently activated, safeguarding workers from potential electrical shocks, burns, or other life-threatening injuries. By following established lockout procedures, employers can comply with safety regulations and provide a secure working environment.

The Importance of Electrical Lockout:

Electrical accidents can have severe consequences, including fatalities, injuries, and property damage. According to the Occupational Safety and Health Administration (OSHA), failure to control hazardous energy accounts for a significant number of workplace accidents each year. Electrical lockout plays a crucial role in preventing such incidents by eliminating the risk of unexpected energization. By adhering to lockout procedures, employers demonstrate their commitment to employee safety and comply with regulatory requirements.

Key Steps in Electrical Lockout:

1. Identify the Equipment: Begin by identifying the specific equipment or machinery that requires lockout. This includes electrical panels, switches, circuit breakers, and any other sources of electrical energy.

2. Notify Affected Personnel: Inform all personnel who may be affected by the lockout, including operators, maintenance workers, and supervisors. Clearly communicate the reasons for the lockout and the expected duration.

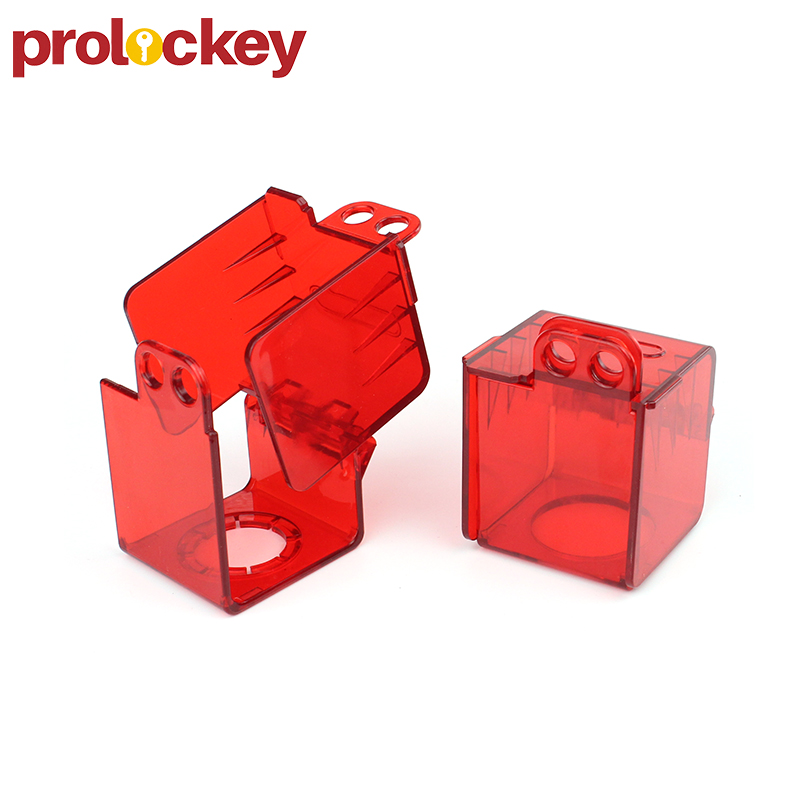

3. Prepare Lockout Devices: Acquire appropriate lockout devices such as padlocks, lockout hasps, tags, and lockout boxes. These devices are specifically designed to prevent unauthorized access and ensure the equipment remains inoperative.

4. Isolate Energy Sources: Identify and isolate all energy sources supplying the equipment. This may involve shutting off power at the main electrical panel, unplugging cords, or blocking energy flow through valves.

5. Apply Lockout Devices: Once the energy sources are isolated, lockout devices should be securely attached to each energy control point. This ensures that the equipment cannot be re-energized until the lockout devices are removed.

6. Verify De-Energization: Before commencing any work, verify that the equipment is de-energized by testing with appropriate voltage detectors or other approved testing devices. This step is crucial to confirm that no electrical energy is present.

7. Perform Maintenance or Repairs: With the equipment safely locked out and de-energized, authorized personnel can proceed with maintenance, repairs, or servicing as required. It is essential to follow all established safety protocols during this phase.

Conclusion:

Electrical lockout is a vital safety procedure that protects workers from electrical hazards in the workplace. By implementing lockout procedures, employers demonstrate their commitment to employee safety and compliance with safety regulations. Understanding the importance of electrical lockout and following the prescribed steps is crucial to ensure a secure working environment and prevent potentially life-threatening accidents. Prioritizing safety through electrical lockout is a responsibility that should never be overlooked.

Post time: Mar-23-2024