Plastic Safety Scaffolding Holder tag SLT01

Plastic Safety Scaffolding Holder tag SLT01

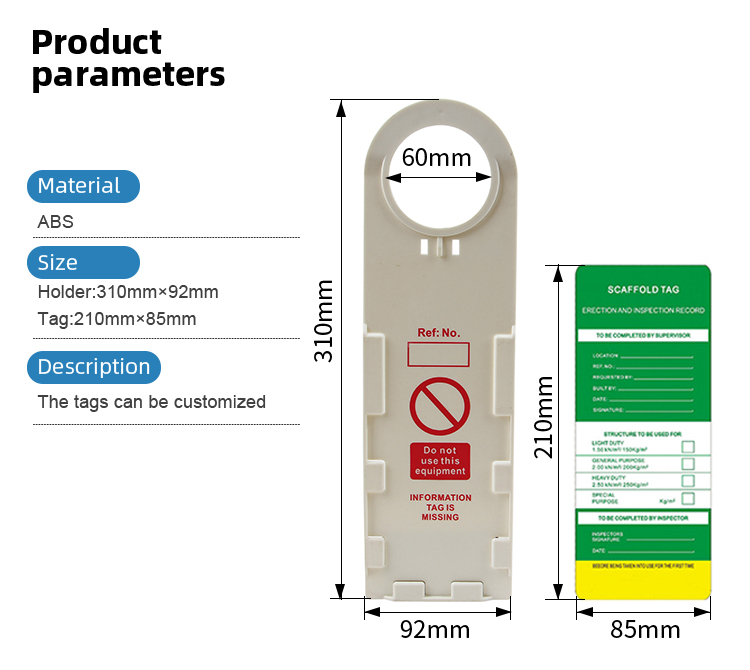

a) The plastic scaffold tag holder is made from ABS, tag is made of PVC.

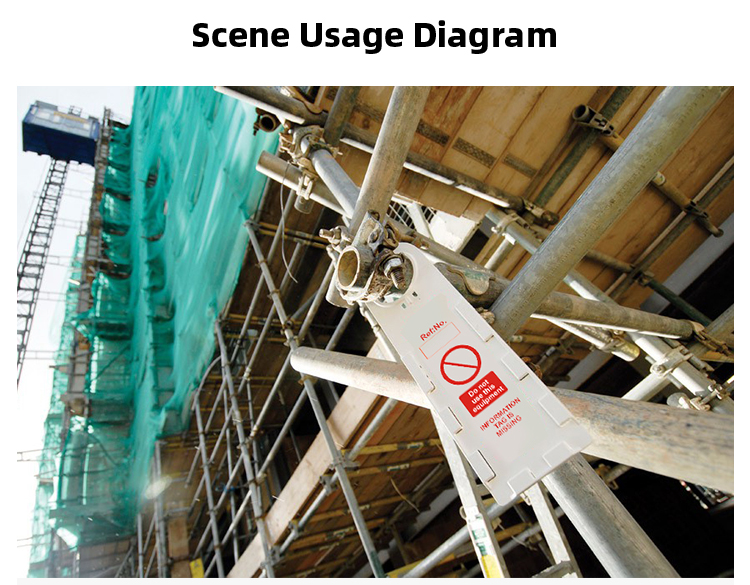

b) Provides system, procedural and legal compliance for scaffolds on work sites.

c) Provides a clear inspection trail giving integrity and control of work carried out.

d) The tags are avaliable in three durable write-on materials, providing highly visual and eye-catching information.

e) Each with a scaffold tag holder and a tag.The tags can be customized.

| Part No. | Description |

| SLT01 | Size:310mm×92mm,Diameter:60mm |

| SLT02 | Size:213mm×56mm |

| SLT03 | Size: 81mm×39mm |

Lock labeling requirements

First of all, durability, locks and signage should be able to withstand the environment being used; Secondly, it should be firm. Lock and signage should be strong enough to ensure that they cannot be removed without borrowing external forces. Also identifiable, the tag should be attached to the lock, indicating the name of the owner and the work being done; Finally, there should be uniqueness, each lock should only be equipped with a key, the key shall not be copied and others shall not be the master of the lock without authorization.

During the equipment debugging, by original isolated single sign, unlock and removal is not isolated in the list “isolation lift” column signature, just behind marked “lift for debugging,” date at the same time, the power equipment of electric transmission and electric debugging personnel by the project team is responsible for, so that we can facilitate in the process of debugging equipment, need test equipment operation, prevent because of frequent start-stop devices, frequently used in a work permit different isolation sheet. The electrical isolator will sign in the column of “Isolation Release” of the original isolation sheet only when the equipment is ready to be put into operation after commissioning. Due to the fact that different work types end the debugging on the same equipment successively, the electrical isolation lock and label should be hung back to the original position when the equipment is not put into operation after the debugging.

Is the person trained to perform the “locking” properly qualified

Whether the locks and locking auxiliary devices and signs meet the safety requirements and are properly managed, and whether the locks are used for personal use

Are there alternative security measures for debugging and other exceptions

Whether the communication in the actual implementation is sufficient, whether the measures are carried out in strict accordance with the procedures, and whether there are corresponding working procedures

Signs are divided into two kinds: general signs and local signs

LOTO master tag: A table representing a specific procedure for a locking device, identifying and describing the power source, locking/release point and method, validation method, and associated risks for the Lockout tagout. Also includes equipment tags

The layout diagram shows the location of the energy isolation points and the corresponding risks.

LOTO Local Signage: The approved local signage is posted directly on the equipment in a standard format, adjacent to the entrance or secured area. It defines the approved methods of energy control and the possible simple tasks to be performed within the danger zone.

Products categories

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top