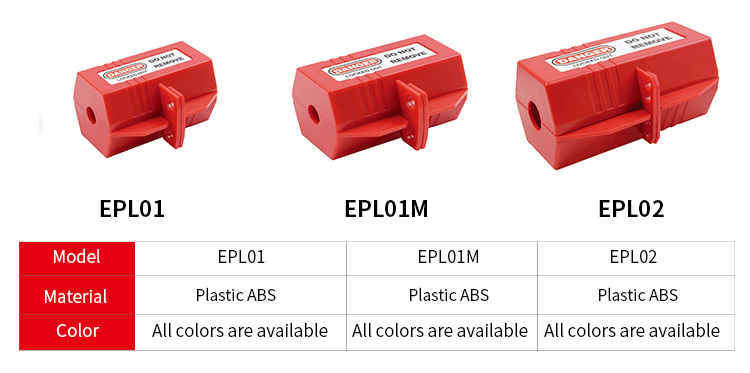

Polypropylene Electrical Plug Lockout Air Conditioner Socket Device EPL01M

Electrical Plug Lockout EPL01M

a) Made from rugged ABS.

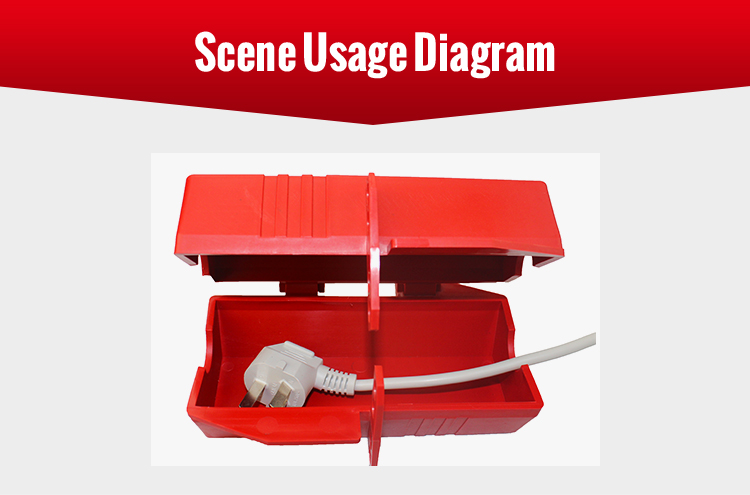

b) Prevent plugs from being into the wall outlet, suitable for all kinds of industrial plugs.

c) The plug completely sits inside the unit with the cable being fed through an access hole inside.

d) Can be locked with2-4 padlocks, lock shackle diameter up to 9mm.

| Part NO. | Description | A | B | C | d1 | d2 |

| EPL01 | For 110V plugs | 89 | 51 | 51 | 12.7 | 9.5 |

| EPL01M | For 220V plugs | 118.5 | 65.5 | 65.6 | 18 | 9 |

| EPL02 | For Large 220V/500V plugs | 178 | 85.6 | 84 | 26 | 9 |

Project Details

Categories:

“Power plug” lock (need to use the plug lock sleeve)

(1) When repairing and maintaining equipment with power plug, the plug must be pulled out from the socket and locked.

(2 the energy isolation measures suitable equipment include: industrial exhaust fan, portable welding machine, welding roller frame displacement, welding, welding smoke filter, car type flame cutting machine, plate chamfering machine, pipe chamfering machine cutting, welding flux drying oven, drying oven, dehumidifier, grinding wheel cutter, dust grinder, vertical sawing machine, bench drill and magnetic drilling machine, manual plasma cutting machine, carbon arc air gouging, hydraulic test pump, mobile hydraulic torque wrench, radial drilling machine, electric lift car mobile cleaning machine, vacuum pump, industrial Ben absorption device, vacuum, spreader, micro heat regenerative dryer, helium mass spectrometer leak detector, horizontal packing machine thrust

(3 for the pressure test pump, mobile radial drilling machine, electric lift car, hydraulic torque wrench mobile cleaning machine, after the power plug is locked, must carry out hydraulic release; For vacuum pump and industrial vacuum cleaner vacuum chuck hanger, after the power plug is locked, the vacuum must be released

Basic requirements for Lockout Tagout management

(1) In order to avoid accidental release of stored energy or materials in equipment, facilities or system areas during unconventional operations, all isolation points of energy and materials should be locked and hung up.

(2) Before implementing the Lockout Tagout, the relevant requirements of the work permit shall be met and the Work Permit Management Procedure shall be specifically implemented.

(3) It is the responsibility of both the territorial unit and the personnel of the operating unit to confirm that isolation is in place and to execute the Lockout tagout before starting the operation.

(4) Under special circumstances, such as the special size of the valve or power switch can not be locked, the person in charge of the local unit can only be signed without the lock, if necessary, take other means to achieve the requirements equivalent to the lock.

(5) When working across shifts, the handover of personal locks should be done well.

(6) The selection of locks shall not only meet the locking requirements, but also meet the safety requirements of the operation site.

Products categories

-

E-mail

-

Whatsapp

-

WeChat

Judy

-

Top