PriceList for Plug Lockout Cover - Combination Portable Departmental and Group Safety Lockout Kit LG07 – Lockey

PriceList for Plug Lockout Cover - Combination Portable Departmental and Group Safety Lockout Kit LG07 – Lockey Detail:

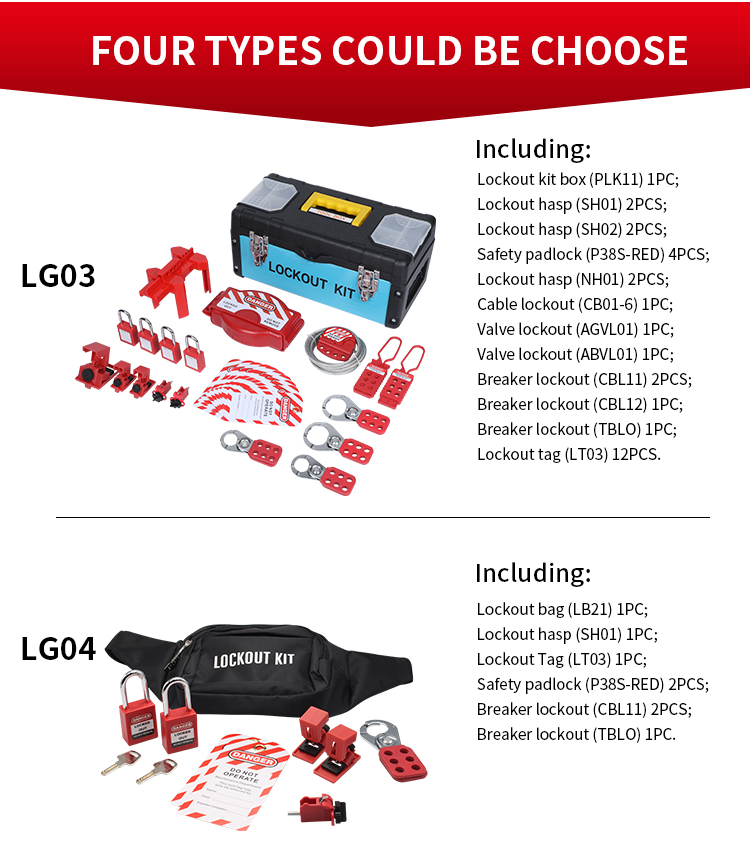

Electrical Lockout Kit LG07

a) It is an industrial selection of lockout/tagout devices.

b) For locking off all kinds of valves, etc.

c) All items can be easily carried in the lightweight carrying tool bag.

d) Tool bag size: 16 inches.

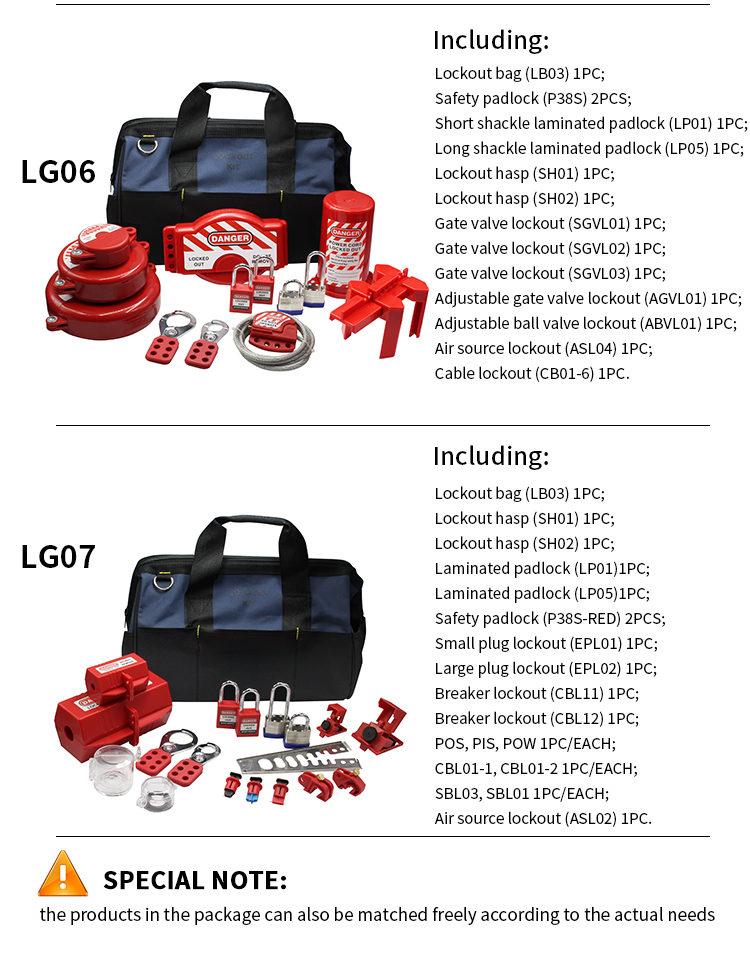

Including:

1. P38S 2PCS

2. SH01/SH02 1PC

3. LP01/LP02 1PC

4. POS PIS POW 1PC

5. CBL11 CBL12 1PC

6. CBL01 CBL02 1PC

7. SBL01 SBL03 1PC

8. EPL01 EPL02 1PC

9. ASL02 1PC

All the following elements should be included in the LOTO program:

Identification of machines, equipment, processes or circuits;

Type and size of energy source (380V power, 90 PSI gas pressure);

List all necessary energy isolation equipment;

Detailed procedural steps to achieve zero energy status (shutdown of machines, energy isolation, fixation and protection of machines, equipment, processes and circuits to control hazardous energy; Releasing stored electrical, kinetic or potential energy);

Complete detailed procedures for “testing” or “validation” to ensure that machines, equipment, processes and circuits are in a state of complete zero energy;

Detailed procedures for the placement, removal and handover of the locking or marking equipment and the responsibilities of the corresponding personnel.

Regular inspection

The energy control procedures are reviewed annually and certified by the Health, Safety and Environmental Coordinator.

The energy control procedure (device-specific energy control procedure) for each machine or type of machine must be checked.

The inspection shall include a review of the locking responsibilities of each individual authorized to lock the machine or device.

The inspector must be authorized to execute the locking procedure being checked. However, inspectors cannot review her on the locking program. However, the inspector could not review her use of the locking program.

Any discrepancies or deficiencies identified shall be addressed immediately.

LOTO training

The training is carried out every year. Authorized employees shall receive training covering the identification of hazardous energy sources, types, and levels of hazardous energy at the site of the patriarch. The means, devices and procedures used for locking, verifying locking or otherwise controlling all stations and all types of equipment (including wire and plug connected devices) will also be examined to accept the transfer of locking responsibilities.

Affected employees shall be trained so that when implementing energy control procedures, they can identify and understand the purpose of the procedures and the importance of not attempting to start or use locked machines or equipment.

Product detail pictures:

Related Product Guide:

Lockout/Tagout FAQ 3

Generator energy isolation-Lock out tag out

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we've acquired rich practical working experience in producing and managing for PriceList for Plug Lockout Cover - Combination Portable Departmental and Group Safety Lockout Kit LG07 – Lockey , The product will supply to all over the world, such as: azerbaijan, Buenos Aires, Roman, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.