Top Suppliers Lockout Tag - Lockout Tagout Kit LG03 – Lockey

Top Suppliers Lockout Tag - Lockout Tagout Kit LG03 – Lockey Detail:

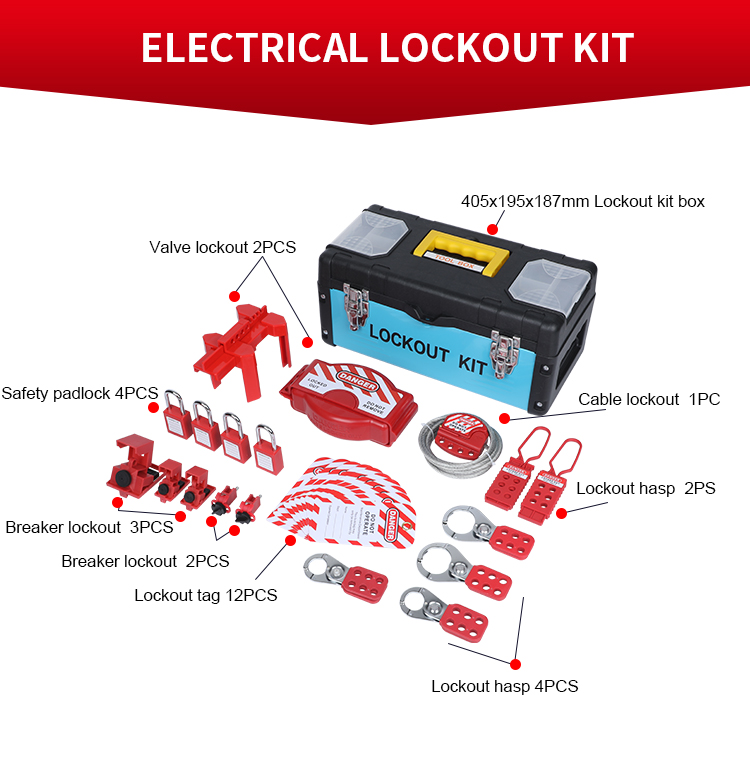

Lockout Tagout Kit LG03

a) It is an industrial selection of lockout/tagout devices.

b) For locking off all kinds of circuit breakers, valves, switches, etc.

c) All items can be easily carried in lightweight carrying tool box.

d) Tool Box Overall size: 410x190x185mm.

Including:

1. Lockout kit box (PLK11) 1PC;

2. Lockout hasp (SH01) 2PCS;

3. Lockout hasp (SH02) 2PCS;

4. Safety padlock (P38S-RED) 4PCS;

5. Lockout hasp (NH01) 2PCS;

6. Cable lockout (CB01-6) 1PC;

7. Valve lockout (AGVL01) 1PC;

8. Valve lockout (ABVL01) 1PC;

9. Breaker lockout (CBL11) 2PCS;

10. Breaker lockout (CBL12) 1PC;

11. Breaker lockout (TBLO) 1PC;

12. Lockout tag (LT03) 12PCS.

Application of the LOTO scheme

Application of the LOTO scheme

This standard applies to, but is not limited to, activities performed on a machine, equipment, process or circuit.

Primary, secondary, stored or separate power sources are locked for service and maintenance purposes. Definition of services and maintenance: repair, preventive maintenance, improvement and installation activities for machines, equipment, processes and wiring. These activities require a machine, equipment, process or circuit, or its components, to be in a “zero energy state”. The person performing these activities must use the Lockout Tagout in accordance with the procedures. An alternative method should be used when the Lockout tagout for machine, equipment, and process routes cannot be used.

All storage energy must be controlled to ensure that the machine is completely safe.

The following is a list of typical activities to which energy control procedures apply:

Build – install – build – repair – adjust

Verify – open – assemble – find and resolve faults – test

Clean – Remove – Maintain – Repair – Lubricate

An alternative can be used if:

The Loto scheme is not feasible

This work behavior is routine, repetitive, and integrated with the production process.

Minor modifications and adjustments to tools, assembly, opening, parts;

No LOTO alternatives are scheduled for the task;

Mission specific training is not provided.

A device with a wired plug for a separate power source may not Lockout a tagout when the plug is disconnected and the authorized person has exclusive control over the disconnection of the power source.

Alternative methods

Finishing Lockout Tagout is always the first choice.

Alternative approaches must be established based on risk assessments of machines, equipment, processes, and circuits.

Such alternative risk assessment and procedures must also include the identification of procedures that need to be implemented prior to the commencement of work, in accordance with other requirements or country-specific regulations, to reduce or eliminate the employee’s exposure to risk

The risk assessment

Risk assessment is used to identify the safest possible conditions for individual operations. The risk assessment establishes safety measures and alternatives that can be used to reduce the likelihood of injury if normal Lockout Tagout procedures cannot be applied. The risk assessment must include the identification and implementation of control measures so that other regulatory requirements can be met.

Shift or personnel changes

The maximum allowable time for each Lockout tagout is the shorter of one shift or the end of the task. It is important to ensure the integrity of the Lockout Tagout procedure either individually or through the use of direct Lockout Tagout handoff, transform lock, or other appropriate means.

The LOTO of contract behavior

It is important that all aspects of the company’s Lockout tagout be adhered to whether the contractor is on a site/running the construction or the company’s personnel are performing the work as the contractor. One of the best practices is to designate a representative authorized by the Company to perform the Lockout Tagout procedure, in which case the external service personnel or contractor should attach their own Lockout Tagout to the same energy isolation device that the Company Representative has locked and hold in place. This is commonly referred to as “the company first up, then down”.

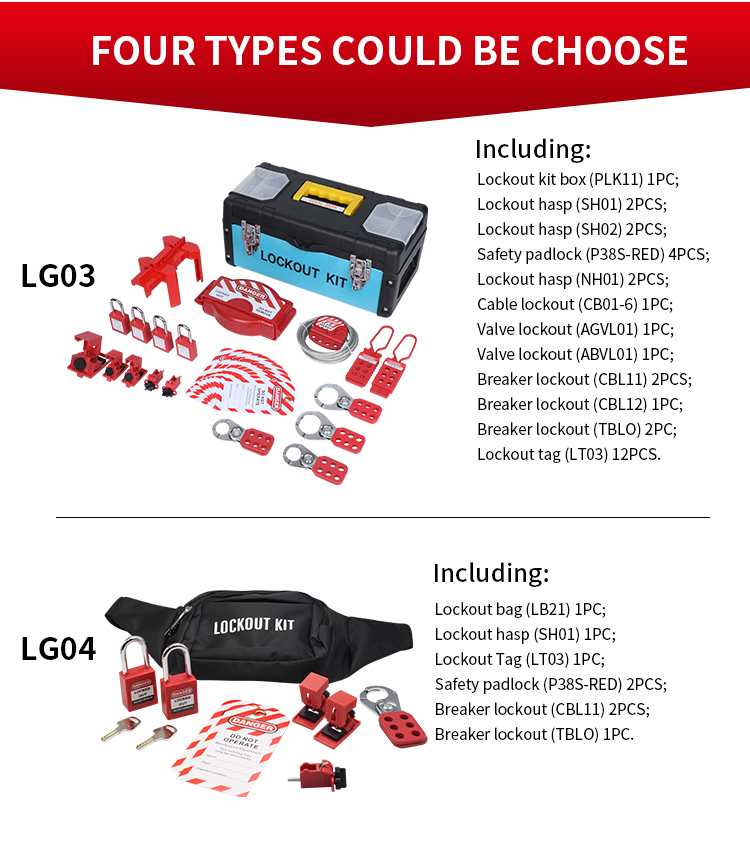

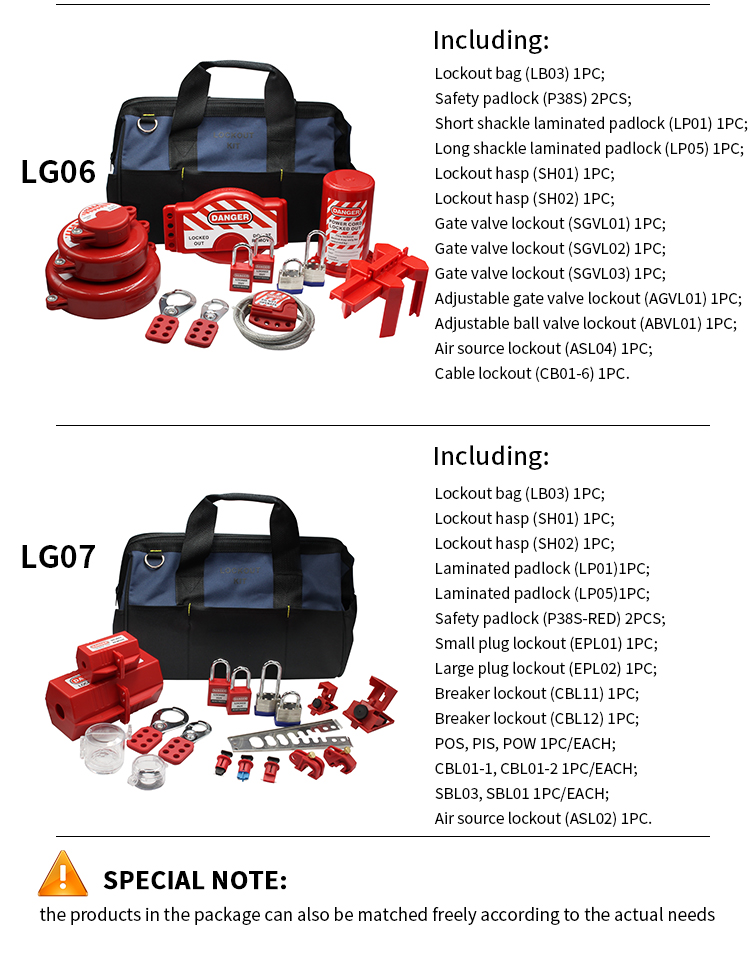

Product detail pictures:

Related Product Guide:

Lockout tagout reduces accidents

Complex locking procedures

Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments for Top Suppliers Lockout Tag - Lockout Tagout Kit LG03 – Lockey , The product will supply to all over the world, such as: Croatia, Washington, Maldives, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!